Posts: 1,156

Threads: 232

Joined: Jan 2016

Reputation:

20

Location: New Haven Ct

sadly they gotta be wired. Ted is 100% correct on how hard it is to accurately drill the nut and axle.

i have done two and both times they came out a tiny bit loose when the holes lined up.

so then you find yourself getting shim washers and carefully adding enough to put the wheel on tight and still be able to pin the nut.

a better approach would be to buy a new axle and have the extra step machined into the new axle.

you'll get an easy to install axle nut already castled with lots more thread to play with when adjusting.

Dave L.

Posts: 1,257

Threads: 100

Joined: Jan 2016

Reputation:

18

Location: Arizona City, AZ

REMEMBER! If you buy Azusa axles, be sure to get the "Flexpruf" which has the ends drilled for cotter pins. TJ

Posts: 384

Threads: 27

Joined: Jan 2016

Reputation:

6

Location: Livermore, CA

05-07-2017, 03:19 PM

(This post was last modified: 05-07-2017, 03:33 PM by Jim Waltz.)

Mel,

There is another way, actually two other ways, to deal with the stubby threads on the GK 800 axle and install a safety clip.

One way is to use a low-height castle nut. These are "AN" nuts, and are available from Aircraft Spruce and other sources. These are also referred to as "shear nuts" as they are indeed lower strength than full-height nuts for holding things in compression on a shaft. They are plenty strong for our uses, however.

I don't like using castle nuts on stepped axles as they did in the old days, because you can never keep the castle nuts tight against the wheel and the step in the axle. Then your wheel wobbles, which will eventually wear the wheel hub and the axle itself. This is why this method of wheel attachment was abandoned long, long ago.

My preferred method, which I use on my buddy Tim's GK 800 and on my '65 SAE, is to use a nylon lock nut, with a clip outboard of the nut. These are low-height nuts, and there is just enough room using them to comfortably drill a hole for a cotter key or a clip. I can send you a picture if you would like. Now, you do have to tighten those nuts quite tight to keep them snug against the wheel and the wheel snug against the step in the axle. About 160 ft-lbs of torque is required, which means you need a long breaker bar - and a way to hold the axle. Bill McCornack makes a tool that slips onto the side of a 1" axle and has a cut in it to engage the key in the axle. It works very nice for this purpose, as you find a place where the tool will be kept from turning by the frame and you just crank away with your breaker bar. Even at this, you still need to check your wheels now and again to see that they are not loose.

And, yes, there are a whole bunch of little "in's and out's" to this vintage karting sport - and very few of them are easy to find out about, except through asking buddies or posing questions on the Forum.

Oh, and I almost forgot. In addition to the nylon lock nut, you really need to use a thin "AN" washer as well. Also available at Aircraft Spruce and elsewhere. Aircraft mechanics need to make sure when they use a castle nut that the cotter pin fits properly in the slot in the nut, so they make these AN washers in standard and light (read "thin") versions, so they can stack up washers to get the right fit. If you should happen to have the original hardware for your Azusa wheels, you will note that the washers under the 1/4" bolts are smaller O.D. than standard SAE washers. That's because they are AN washers. A goodly number of the original guys involved in the early days of karting were veteran WW-II aircraft mechanics, and I think the aircraft hardware was something that they brought with them from their military experience. Part of the history of our sport......

Jim Waltz, West Sacramento, CA

Posts: 412

Threads: 34

Joined: Mar 2017

Reputation:

7

Location: East of DFW

(05-07-2017, 11:19 AM)ted johnson Wrote: (05-07-2017, 10:22 AM)Mel Ruffner Wrote: Dave I checked my axle and yes it has 2steps and threaded part. Now I have another question. The axle has a threaded nut on the end ,but not drilled for cotter key and I don,t think there!s room to drill one.Would I be able to run it at a vka event or the big one ? Is there someway to safety wire it , with out drilling a hole in it?

Mel, the axle undoubtedly came from a Go Kart 800, along with the wheels. These axles were notorious for being too short for a cotter pin outboard of the axle nut. The common solution is to drill through the flat of the nut and the axle. It's a difficult thing to line up the holes for drilling unless you can drill the nut and axle after assembly. It's hard to do that, because the nut is recessed too far from the rim of the wheel. If you can drill through all the flats, you have a better chance of lining things up. Some CAREFUL measurements are required. I've done a couple, but not easily! Ted

Isn't that the reason everything started coming with castle nuts?

Posts: 368

Threads: 183

Joined: Feb 2017

Reputation:

7

Location: Toledo, OHJ

(05-06-2017, 06:59 PM)Jim Waltz Wrote: (05-06-2017, 06:43 PM)Mel Ruffner Wrote: Scott your kart looks great I, be happy if mine looks half as good as yours.Thankyou everyone for your Imput. I got a lot to learn.What did we ever do without Internet, so much info and you guys are great

Mel,

One thing you should know about your first generation Azusa aluminum wheels is that they take an axle that steps down from 1" to 7/8" to 3/4". This is not at all obvious just glancing at the wheels and the axle, but is very important, as almost all the vintage wheels go 1" to 3/4".

If you have the axle that the wheels were on, that would be a pretty rare combination of parts. Someone wanting to restore a Go Kart 800 would be very interested in them.

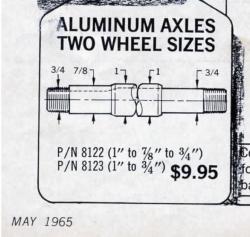

FYi. I came across this Karting World (May 1965) AZUSA ad today with two axle styles. Is this what you are speaking of Jim?

Posts: 384

Threads: 27

Joined: Jan 2016

Reputation:

6

Location: Livermore, CA

(05-11-2017, 03:05 PM)Scott Elkes Wrote: (05-06-2017, 06:59 PM)Jim Waltz Wrote: (05-06-2017, 06:43 PM)Mel Ruffner Wrote: Scott your kart looks great I, be happy if mine looks half as good as yours.Thankyou everyone for your Imput. I got a lot to learn.What did we ever do without Internet, so much info and you guys are great

Mel,

One thing you should know about your first generation Azusa aluminum wheels is that they take an axle that steps down from 1" to 7/8" to 3/4". This is not at all obvious just glancing at the wheels and the axle, but is very important, as almost all the vintage wheels go 1" to 3/4".

If you have the axle that the wheels were on, that would be a pretty rare combination of parts. Someone wanting to restore a Go Kart 800 would be very interested in them.

FYi. I came across this Karting World (May 1965) AZUSA ad today with two axle styles. Is this what you are speaking of Jim?

Mel, even though it shows a 1" to 7/8" to 3/4", that is not the same as a Go Kart 800 axle. The GK 800 axle has a square shoulder at the 1" to 7/8" step down. The nut holds the wheel against that shoulder. What you show has a chamfer at that point.

Jim Waltz, West Sacramento, CA

Posts: 1,257

Threads: 100

Joined: Jan 2016

Reputation:

18

Location: Arizona City, AZ

I hafta like the "Resident Genius" moniker, Jimmy! Ted

|